Implementing a quality management system (QMS) can transform the way your organisation operates. For many businesses, ISO 9001:2015 certification is the first step towards improved efficiency, customer satisfaction, and international recognition.

If you are new to ISO, this guide will walk you through everything you need to know about how to become ISO 9001:2015 certified. From understanding the requirements to preparing for your certification audit, we will cover each step in detail so that you feel confident starting your journey.

What is ISO 9001:2015?

ISO 9001:2015 is the international standard for quality management systems (QMS), developed by the International Organization for Standardization (ISO). It sets out criteria that any organisation can follow to demonstrate its ability to consistently provide products and services that meet customer and regulatory requirements.

The standard focuses on:

- A process approach to business operations.

- Risk-based thinking for decision-making.

- Continuous improvement through the PDCA (Plan-Do-Check-Act) cycle.

- Meeting customer needs and improving satisfaction.

For businesses, ISO 9001:2015 is more than a certificate, it is a framework for building trust, improving efficiency, and strengthening quality control across all processes.

Step 1: Understand ISO 9001:2015 Requirements

Before beginning ISO 9001:2015 implementation, you must understand the requirements of the standard.

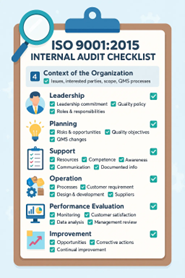

ISO 9001:2015 contains 10 clauses, with Clauses 4–10 outlining the mandatory requirements for a quality management system (QMS):

- Clause 4: Context of the Organisation

- Clause 5: Leadership

- Clause 6: Planning

- Clause 7: Support

- Clause 8: Operation

- Clause 9: Performance Evaluation

- Clause 10: Improvement

Each clause helps you structure your QMS around leadership commitment, operational control, monitoring, and continuous improvement.

Step 2: Perform a Gap Analysis

A gap analysis compares your current systems with ISO 9001:2015 requirements. It helps you:

- Identify what already meets the standard.

- Highlight areas that need improvement.

- Create a roadmap for ISO 9001:2015 implementation.

Many organisations work with specialists in ISO 9001:2015 consulting at this stage, as it helps avoid missing critical requirements. A gap analysis report also gives management a clear action plan before investing time and resources.

Step 3: Secure Top Management Commitment

ISO 9001:2015 certification cannot succeed without top management commitment. Leaders play a vital role in:

- Aligning the QMS with the organisation’s strategic direction.

- Providing resources for ISO 9001:2015 implementation.

- Establishing a quality policy and measurable objectives.

- Leading by example to promote a culture of quality.

When top management is engaged, employees are more likely to adopt quality control measures in their daily work.

Step 4: Define the Scope of Your QMS

Not every part of your organisation may fall under the QMS. Defining the scope means identifying which operations, departments, and products or services will be included.

For example:

- Consider external and internal issues (Clause 4.1).

- Identify interested parties and their needs (Clause 4.2).

- Define the boundaries of products and services (Clause 4.3).

Exclusions, such as product design, must be clearly justified. This ensures the QMS reflects your actual operations.

Step 5: Develop the QMS Documentation

ISO 9001:2015 requires documentation that supports your QMS. This includes:

- A quality policy and objectives.

- Descriptions of processes and their interactions.

- Documented procedures for critical operations.

- Records that demonstrate compliance.

Your documentation should be structured using the PDCA cycle, which helps you plan, implement, monitor, and improve processes.

Step 6: Implement the QMS

Once documented, your QMS must be put into action. This involves:

- Training employees on their specific roles.

- Maintaining quality records.

- Communicating the quality policy organisation-wide.

- Monitoring and measuring processes to ensure compliance.

Implementation is the stage where theory becomes practice. For many companies, external ISO 9001:2015 consulting helps accelerate this phase and avoids common mistakes.

Step 7: Conduct Internal Audits

Internal audits are a key requirement of ISO 9001:2015 (Clause 9.2). They ensure your QMS is effective and identify areas for improvement.

Key points to remember:

- Train impartial internal auditors.

- Audit all processes regularly.

- Record findings and take corrective action.

Internal audits should be seen as a positive tool, not only for conformance but also for strengthening efficiency and quality control.

Step 8: Perform a Management Review

Top management must regularly review the QMS to ensure it remains effective and aligned with business strategy. Reviews should cover:

- Audit results

- Customer feedback

- Key performance indicators (KPIs)

- Risks, opportunities, and improvement actions

This ensures the QMS is not a one-time exercise but a dynamic system that evolves with your organisation.

Step 9: Take Corrective Actions

When non-conformities are found, corrective actions must be taken. According to Clause 10.2:

- Identify the root cause

- Implement corrective action

- Monitor its effectiveness

- Prevent recurrence

A strong corrective action process is central to quality control and helps build customer confidence.

Step 10: Select a Certification Body

To achieve certification, you must choose an accredited third-party certification body. Consider:

- Accreditation recognition

- Industry experience

- Cost and reputation

A reputable body ensures your ISO 9001:2015 certificate is internationally recognised.

Step 11: Undergo the Certification Audit

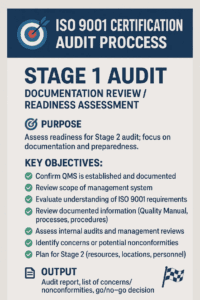

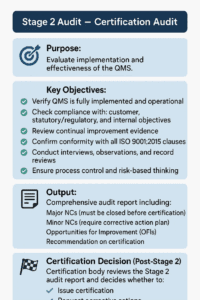

The certification audit is conducted in two stages:

- Stage 1 – Documentation Review: The auditor evaluates your QMS documents.

- Stage 2 – Main Audit: The auditor visits your organisation to assess how effectively the QMS has been implemented.

If you meet the requirements, you move on to certification.

Step 12: Address Audit Findings

If non-conformities are identified, you must provide a corrective action plan. Once evidence is submitted and accepted, the certification process continues. Addressing issues promptly shows auditors your commitment to continuous improvement.

Step 13: Receive Your ISO 9001:2015 Certificate

Once successful, your organisation receives an ISO 9001:2015 certificate valid for three years, subject to:

- Annual surveillance audits.

- A re-certification audit at the end of the cycle.

This ensures your QMS continues to meet ISO standards over time.

Tips for Success in ISO 9001:2015 Certification

- Start early with document control: A web-based solution simplifies record-keeping.

- Provide training at all levels: Employees must understand their role in the QMS.

- Align ISO 9001:2015 implementation with business goals: This ensures long-term value.

- Use ISO 9001:2015 consulting services: Professionals help reduce risks and save time.

How WWISE Can Help

At WWISE, we support organisations through every stage of ISO 9001:2015 implementation. Our services are designed to improve quality, efficiency, and competitiveness, including:

- ISO and SHEQ Systems Implementation: Helping you build a management system aligned to ISO and national standards.

- Employee Training: Accredited training across all levels, customised for industries from manufacturing to telecommunications.

- Customised Web-Based Solutions: Integration of ISO requirements with Office 365, SharePoint, or other platforms for seamless document control.

With years of expertise in ISO 9001:2015 consulting and implementation, WWISE is your trusted partner in achieving and maintaining ISO certification.